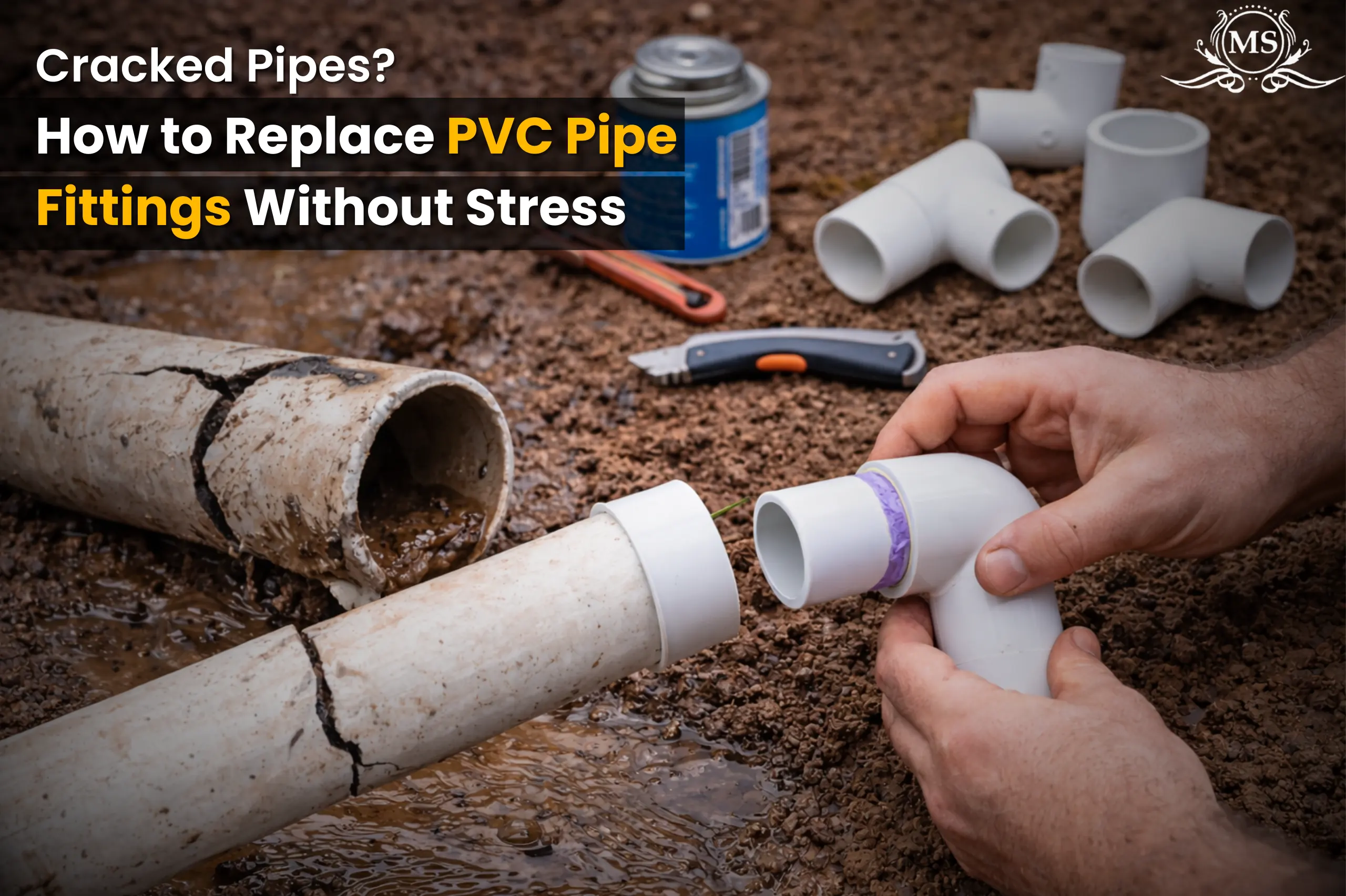

A pool of water under your sink or a damp patch on your wall can make you cringe. They indicate your pipe has cracked. A cracked pipe can sound like a structural nightmare. The cause of this is a faulty fitting. The PVC pipe fittings need to be replaced. This process can however be pretty stressful. So, how to replace it without stress? Thankfully, modern PVC pipes and fittings are extremely robust. They are designed for easy, stress-free repairs. Learning how to manage PVC pipe fittings for homeowners is among the most empowering DIY skills. It saves from hefty plumbing bills. It also prevents long-term water damage to your property.

THE ROLE OF PVC PIPES & FITTINGS

Table of Contents

TogglePVC (Polyvinyl Chloride) has become for residential plumbing the gold standard. Its robust durability and strong chemical resistance with ease of installation makes it the gold standard that it is for residential plumbing. The pipes can last decades. But PVC pipe fittings (the joints, turns, and connectors are often the weak points where leaks occur.

Cracks in pipe fittings can happen for the following reasons:

- IMPROPER INSTALLATION: Occurs due to the use of wrong glue. Or not allowing sufficient ‘cure time.’ l

- TEMPERATURE SWINGS: Extreme cold. They can make PVC brittle.

- PHYSICAL IMPACT: Accidental bumps in high-traffic areas.

HOW TO IDENTIFY THE RIGHT PARTS?

You need to exactly know before you head to the hardware store what you are looking for. Using the wrong components will only complicate your situation. It is in fact the quickest way to add stress to your project. The following details common types of PVC pipe fittings used in a standard home.

| FITTING TYPE | PURPOSE | BEST USED FOR… |

|---|---|---|

| Coupling | Connects Two Pipes Of The Same Diameter In A Straight Line | Repairing A Cut Section Of Pipe |

| Elbows (90° or 45°) | Changes The Direction Of The Pipe Run | Navigating Around Corners Or Obstacles |

| Tee | A T-Shaped Fitting With One Inlet & Two Outlets | Branching off a Water Or Drain Line |

| Union | Similar To a Coupling But Can Be Unscrewed | Areas that may need future maintenance (Pumps) |

| Adapter | Connects PVC To Different Materials (Metal) | Connecting a PVC Pipe to a Threaded Faucet |

| Cap / Plug | Seals The End of Pipe | Permanent Or Temporary Closure of a Line |

STRESS-FREE REPLACEMENT GUIDE: STEP-BY-STEP

You don’t require a master’s degree in plumbing to replace a cracked fitting. You need a calm approach with the right sequence of actions. The following details the steps for a permanent leak-free fix.

PHASE 1: PREPARATION

Most DIYers tend to rush initially. That’s a huge mistake. This should be avoided. Instead follow the below process.

SHUT OFF THE WATER:

- Locate your main water valve. Or the local shut-off under the sink.

- Drain the lines by opening the lowest faucet in the house.

GATHER YOUR TOOLS:

- You will need for your repair,

- Hacksaw (or PVC Cutter);

- Sandpaper (120 grit);

- Tape Measure; and

- PVC Pipes & Fittings specific to your repair.

SAFETY FIRST:

- Wear safety glasses. PVC primer and cement are chemical-heavy.

- Ensure the area is well-ventilated.

PHASE 2: REMOVING THE DAMAGED FITTING

- MARK YOUR CUTS: Make sure an inch of space on either side of the crack.

- CUT: Use a hacksaw to cut through the pipe. Try to keep the cut as ‘square’ (90 degrees) as possible. A crooked cut will prevent the pipe from seating fully into the new fitting. This leads to leaks.

- DEBURR: Use your sandpaper or a utility knife to remove from the cut ends the ‘burrs’ (rough plastic bits). A smooth surface is critical for a chemical weld.

PHASE 3: THE ‘DRY FIT’ TEST

Assemble your new PVC pipe fittings before you touch the glue onto the pipes.

- Push the pipes into the fittings. This ensures everything lines up.

- Use a marker to draw a line across the fitting and the pipe. This ‘alignment mark’ will help you instantly find the right position once the glue is applied.

PHASE 4: THE CHEMICAL WELD (GLUING)

PVC ‘glue’ is not actually glue. It is a solvent that melts the plastic to combine the pieces together.

- APPLY PRIMER: Coat the insides of the pipe and fitting with purple primer. This cleans the surface and also softens the plastic.

- APPLY CEMENT: Apply immediately a thin, even layer of PVC cement over the primed areas.

- THE TWIST AND HOLD: Push the pipe into the fitting, aligning the marker lines. Then, give it a quarter-turn as you push. This helps to spread the cement evenly.

- HOLD FIRM: Hold the joint together for 30 seconds. If you let go too soon, the pressure could push the pipe back out of the fitting.

MAINTENANCE TIPS FOR LONG-LASTING PVC SYSTEMS

AVOID OVER-TIGHTENING:

- Hand-tight plus a half-turn with a wrench for threaded PVC pipe fittings is plenty.

- Avoid over-tightening. They cause stress fractures.

INSULATE FIR WINTER:

- Opt for foam sleeves on exposed outdoor pipes.

- Help prevent the freeze-thaw cycles that crack plastic.

USE THE RIGHT CEMENT:

- Ensure your solvent is specifically labeled for PVC (not CPVC or ABS). That’s because the chemical compositions differ.

CONCLUSION

PVC Pipe Fittings’ replacement is a straightforward task. They yield immediate outcomes. You can by understanding the varied types of PVC pipe fittings and adhering to a methodical installation process, transform into a simple afternoon fix, a stressful cracked pipe situation. When you buy PVC pipes and fittings from Mahavir Group you buy high-quality products for a leak-free home.

FAQs

Q. How to choose the right PVC pipe fittings for a repair?

A. There are different types of PVC pipe fittings. You must match the pipe’s ‘Schedule’ (usually Schedule 40 or Home Plumbing) and its diameter.

- Use a Coupling for straight-line repairs.

- Use an Elbow to fix leaks at a corner.

- Use a Union. They offer the ability to easily disconnect the pipe in the future without cutting it again.

Q. Is it possible to fix a cracked pipe without having to replace the entire section?

- A. You can use temporary solutions for minor hairline cracks. Like for instance, epoxy putty or fiberglass resin tape. For a permanent fix, you need to replace the damaged PVC pipe fittings or a small section of the pipe. Solvent welding like the use of primer and cement creates a chemical bond. They are often stronger than the pipe itself.

Q. How does PVC pipe fittings crack?

A. Some common causes that leads to cracks in PVC pipe fittings are:

- THERMAL STRESS: Rapid temperature changes. They cause expansion and contraction.

- OVER-TIGHTENING: Applying excess force to threaded fittings.

- INCOMPATIBILITY: Using the wrong type of solvent cement. Or skipping the primer. They lead to weak, brittle points.

- PHYSICAL IMPACT: High-traffic areas. Pipes are can get accidently bumped or kicked.

Q. How long should I wait after repair work to turn the water back on?

A. Most experts suggest waiting

- For non-pressure drain lines, at least 2 hours.

- For high-pressure water supply lines for up to 24 hours before fully opening the main valve.

Q. Is it really essential to use purple primer on my PVC pipes and fittings?

- A. Yes. Purple primer serves two critical roles. It cleans away grease and dirt. It also chemically softens the plastic. They allow the cement to fuse the two pieces together. Skipping primer often results in ‘dry joints’ that look initially fine but will fail under pressure eventually.