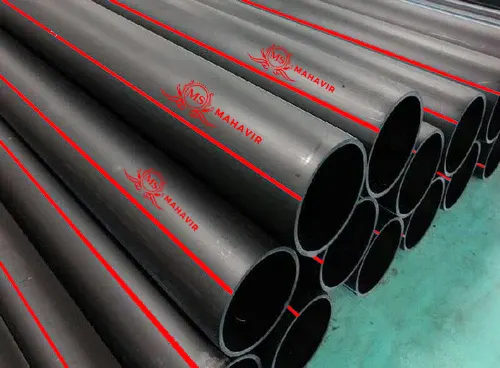

Welcome to Mahavir, a leading provider of high-quality HDPE Pipes designed to meet diverse piping needs across industries. Our HDPE Pipes are engineered with precision and expertise, offering durability, reliability, and efficient performance in various applications.

Mahavir HDPE Pipes stand as a testament to innovation and excellence. Crafted using advanced technology and premium-grade materials, these pipes are engineered to withstand challenging environments while ensuring efficient fluid conveyance.

Experience the reliability and efficiency of Mahavir HDPE Pipes, designed to meet the demanding needs of various industries. Contact us today to explore our range of HDPE Pipes tailored to suit your specific piping requirements.

HDPE pipes for various applications from water distribution to industrial systems, is among the most efficient, durable solutions. Go no further for the best HDPE pipe in Delhi than MAHAVIR Group. MAHAVIR Group, be it for construction or water management or a related industry, is among the best HDPE pipe manufacturers in Delhi.

Before proceeding further, know – what is HDPE pipe?

It indicates a kind of plastic pipe that’s made from petroleum. Known for its high-strength-to-density ratio, it is

Widely used for a range of applications, it comes in

This makes it suitable for long-lasting, cost-effective piping solutions. Like, in the construction of

Often its asked, which is better – HDPE or PVC Pipe?

Both are highly versatile pipes with distinct advantages. The following details tells which one is better,

VERDICT– In durability, HDPE pipe is better. It suits areas subject to heavy impact or harsh weather conditions.

VERDICT– HDPE pipes’ flexibility reduces during installation, the risk of fractures.

VERDICT – Long-term cost-effectiveness makes HDPE pipes for many applications, a better investment.

VERDICT– HDPE pipes during installation often require specialized welding. PVC pipes on other hand, can be joined with simple adhesives’.

HDPE pipes are more environment-friendly. As it is easier to recycle. It also causes lower environmental footprint.

Overall in HDPE pipe VS PVC pipe, HDPE pipes score better. They suit systems requiring long-term durability and reliability. PVC pipes on other hand, are suitable for lower-cost, smaller-scale applications.

You can find in Delhi some of India’s best HDPE pipe manufacturers and suppliers. It’s important to choose, be it for large-scale commercial projects or smaller applications, the best of HDPE pipe fittings suppliers. That offer competitive HDPE pipe price lists with no compromise on quality.

When it comes to high-quality HDPE pipes sourcing in Delhi, fewer better options exist than MAHAVIR Group, among the top HDPE pipe suppliers.

It offers top-tier HDPE products that comply with international standards at affordable prices. You can find at MAHAVIR Group, a wide array in varied sizes from 12mm-500mm HDPE pipe, with different pressure ratings.

HDPE pipe sizes come in different HDPE pipe dimensions and variations catering to different applications.

Your HDPE pipe size selection choice should depend on the varied factors. Factors like type of application, required flow rate, and pressure conditions.

You can find be it for construction of a residential irrigation system OR designing a large-scale industrial infrastructure, the right HDPE pipe sizes at MAHAVIR Group for your needs.

HDPE pipe specifications to determine the pipe’s suitability for a specific application, are critical

An HDPE pipe’s pressure rating is critical. Determines maximum pressure it can withstand. Common pressure ratings include, PN6, PN8, PN10, and PN16. They indicate the pressure in bar that can be handled by the pipe.

2. PIPE THICKNESS:

HDPE pipes are designed depending on the application, with varied well thicknesses. The thicker the pipe wall, the more the pressure the pipe can handle.

3. STANDARD LENGTHS:

HDPE pipes are available depending on the application, in standard lengths of 6 meters or coils. Coiled pipes are used often for installations over long distances.

4. MATERIALS:

HDPE pipes are most often manufactured with high-class polyethylene resins. That ensures excellent resistance to corrosion and chemicals.

HDPE pipe, coils and HDPE Pipe fittings have in the integrity and functionality of the HDPE piping system, a critical role to play.

2. HDPE PIPE COILS: Flexible pipes that

HDPE pipe installation has a specific procedure. They ensure optimal performance. There are two primary HDPE pipe welding methods of joining HDPE pipes. They include Electrofusion Welding, AND Butt Welding.

Proper and secure installation for the longevity of HDPE pipes is essential.. The pipes should be installed with the right alignment at the proper depth. This helps to avoid over time, chances of damage or deformation.

➡️ Read More :- About underground plastic water tank

You need to know for planning, installation, and transportation, HDPE pipe weight chart. The pipe’s weight depending on its size and thickness, varies. A typical HDPE pipe weight chart will assist you to estimate for each pipe’s type and size, total weight. Larger diameter pipes generally have more mass and require during installation more handling equipment.

HDPE pipe lifespan is typically long. They can last for up to 50 to 100 years. This however depends on environmental factors and the pipe’s application. They are highly resistant to corrosion. This reduces the need for frequent maintenance. The pipes with minimal upkeep can provide for piping systems, a long-term, cost-effective solution.

Mahavir HDPE Pipes offer reliable and consistent performance, ensuring long-term durability and minimal maintenance.

Mahavir HDPE Pipes contribute to environmental sustainability through their recyclability and eco-friendly nature.

With 21+ years of experience, we have a proven track record of delivering top-notch HDPE Pipe solutions to satisfied customers.

Mahavir HDPE Pipes are known for their exceptional durability, corrosion resistance, and versatility. They are designed to withstand harsh environmental conditions, ensuring efficient fluid conveyance with minimal friction.

Mahavir HDPE Pipes are suitable for applications in agriculture (irrigation systems, water supply, drainage), construction (sewerage, drainage systems), and various industrial uses (conveying chemicals, slurries, and fluids).

Mahavir conducts stringent quality checks on their HDPE Pipes, ensuring adherence to industry standards and superior performance. Their commitment to quality assurance guarantees long-term reliability and customer satisfaction.

Mahavir provides a wide range of HDPE Pipes in various sizes and types to cater to diverse needs across different industries. This versatility allows customers to select the appropriate pipe specifications for their specific applications.

Yes, Mahavir HDPE Pipes are built with materials that resist corrosion and degradation, ensuring longevity and reliability even in challenging environments.

Mahavir HDPE Pipes are engineered to withstand varying pressure levels, making them suitable for both low and high-pressure applications across different industries.

Mahavir's team of experts provides comprehensive support, guiding customers through the selection, installation, and maintenance processes of their HDPE Pipes.

To place an order for Mahavir HDPE Pipes, you can contact them directly at (+91) 99963-56000 or visit their website for more information. Their customer service team is available to assist with inquiries and order placements.

Mahavir Group of Companies believes in a sustained process of innovation and diversification of its products.

Opening Hours: Mon – Sat: 10.00 – 7:00

Get In Touch

Copyright © 2024 Mahavir Group of Companies | All Rights Reserved | Powered by OptMum Digital

Not a member? Create an account

Already got an account? Sign in here